Products >> Hydraulic Filter Element >> Hydac Filter Element

HYDAC Filter Element

- Product No.:0660 D 010 BH4HC

- Brand:HYDAC

- Place of Origin:Germany

Product description:

Germany HYDAC Technology GmbH specializes in the production of components and devices for fluid filtration technology, hydraulic control technology, electronic measurement technology, is a world famous hydraulic parts manufacturer of filters, accumulators, hydraulic valves, electronic products, pipe clips, electromagnets, hydraulic system assembly and other products. The application range of HYDAC products is very wide, covering almost all walks of life, especially in the metallurgical industry, automotive industry, power equipment, chemical industry, construction machinery, paper industry, shipbuilding industry and machine tool manufacturing and other fields are widely used.

HYDAC filter element ensures the function and service life of hydraulic components with its high quality and performance. The filter element is folded in star shape, and the flow direction is from outside to inside

Filter material:Betamicror °,Aquamicron®, metal fiber, metal mesh, paper, glass fiber,ECOmicron®, synthetic fiber.

Filtration accuracy: 3μm,5μm, 10μm,20μm,25μm,50μm, 100μm,200μm'

Working pressure::10bar~210 bar

Ambient temperature: -30℃... + 100 ℃

Applicable media: mineral oil, lubricating oil, synthetic and biodegradable oil;

Germany HYDAC Technology GmbH specializes in the production of components and devices for fluid filtration technology, hydraulic control technology, electronic measurement technology, is a world famous hydraulic parts manufacturer of filters, accumulators, hydraulic valves, electronic products, pipe clips, electromagnets, hydraulic system assembly and other products. The application range of HYDAC products is very wide, covering almost all walks of life, especially in the metallurgical industry, automotive industry, power equipment, chemical industry, construction machinery, paper industry, shipbuilding industry and machine tool manufacturing and other fields are widely used.

HYDAC filter element ensures the function and service life of hydraulic components with its high quality and performance. The filter element is folded in star shape, and the flow direction is from outside to inside

Filter material:Betamicror °,Aquamicron®, metal fiber, metal mesh, paper, glass fiber,ECOmicron®, synthetic fiber.

Filtration accuracy: 3μm,5μm, 10μm,20μm,25μm,50μm, 100μm,200μm'

Working pressure::10bar~210 bar

Ambient temperature: -30℃... + 100 ℃

Applicable media: mineral oil, lubricating oil, synthetic and biodegradable oil;

Product features:

- Efficient and accurate filtration: The special structure of the filter disc filtration technology, accurate and sensitive performance, to ensure that only particles smaller than the required size can enter the system, is the most effective filtration system; Specifications are 5μ, 10μ, 20μ, 55μ, 100μ, 130μand 200μ. users can choose different precision filter disks according to water requirements. System traffic can be flexibly adjusted as required.;

- Standard modular, save land: The system is based on the standard disk filter unit, according to the modular design, users can choose according to demand, flexible, strong interchangeability. The system is compact, occupies a small area, can flexibly use the corner space for installation, such as the treatment water 300m3/h about the equipment covers an area of only about 6m2(general water quality, filtration grade 100μs). Automatic operation, continuous water discharge: in the filter combination between each unit, the backwash process takes turns, automatic switch between working and backwash state, can ensure continuous water discharge; Backwash water consumption is very little, only accounting for 0.5% of the water output; If with air auxiliary backwash, water consumption can be reduced to less than 0.2%. High-speed and thorough backwash, only tens of seconds to complete.

- Long life: the new plastic filter element is strong, no wear, no corrosion, very little scaling, after years of industrial practical verification, the use of 6 to 10 years without wear, not aging, filtration and backwash effect will not be worse because of the use of time.

- High quality, less maintenance: products meet the corresponding quality standards, all products before leaving the factory are tested and tested under simulated conditions, no special tools, few parts; Easy to use, requiring only regular inspection and almost no routine maintenance.

Installation

-

in return line filters (element type R)

-

in return line filters to DIN 24550 (element type RN)

-

in inline filters (element type D)

-

in inline filters to DIN 24550 (element type DN)

-

in inline filters MFX (element type MX)

- in return line suction filters (element type RK)

- in suction filters (element type RS)

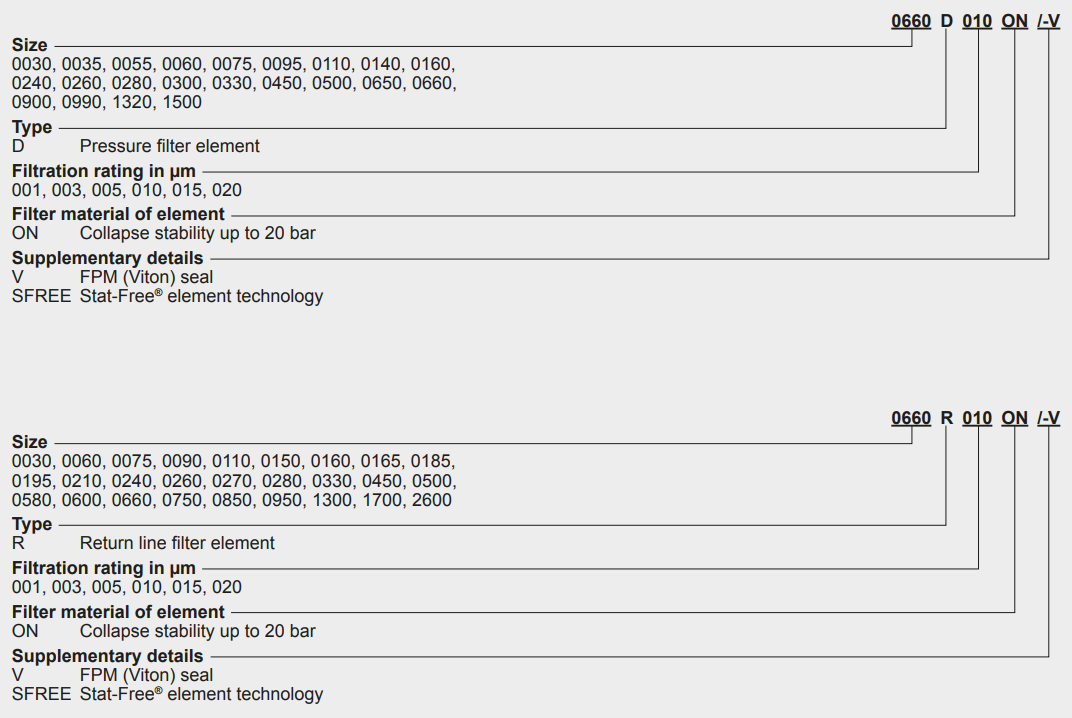

Model Code

- metallurgy: used for rolling machine, continuous casting machine hydraulic system filtration and filtration of various smooth equipment.

- Petrochemical: the separation and recovery of commodities and base commodities in the production process of oil refining and chemical industry, liquid purification, tape, CD and film purification in production, oilfield well water and natural gas particle removal filtration.

- textile: polyester melt in the process of drawing purification and uniform filtration, air compressor maintenance filtration, compressed gas removal of oil and water.

- electronics and pharmaceutical: reverse osmosis water, deionized water treatment filtration, washing liquid and glucose pretreatment filtration.

- mechanical processing equipment: paper machinery, mining machinery, injection molding machine and large precision machinery of smooth system and air purification of compressed air, tobacco processing equipment and spraying equipment dust recovery and filtration.

- railway internal combustion engine and generator: smooth oil and oil filtration.

- car engine and construction machinery, ships, trucks with a variety of hydraulic oil filter.

- Smooth system of gas turbine and boiler, speed control system, oil purification of bypass control system, purification of water pump, fan and dust removal system.

- all kinds of lifting and transfer work: lifting, loading and other engineering machinery to fire, repair, transfer and other special vehicles, ship winch, windlass, blast furnace, steelmaking equipment, lock, ship door opening and closing equipment, theater Elevator pit and elevator stage, all kinds of automatic transport lines.all kinds of demand for pushing, squeezing, pressing, shearing, cutting, excavating and other working equipment: hydraulic press, metal data die-casting, molding, rolling, calendering, stretching, shearing equipment, plastic injection molding machine, plastic extrusion

- Machinery and other chemical machinery, tractors, harvesters and other cutting, mining agricultural and forestry machinery, tunnel, mine and ground excavation equipment, all kinds of ship steering gear.high care, high precision control: high precision positioning system of processing machine tools, industrial robot drive and control, metal plate pressure, leather slice thickness control, power station generator speed control, high performance

- Vibration table and testing machine, large motion simulator with many degrees of freedom, etc.

- a variety of work program combination of automatic operation and control: combination of machine tools, automatic machining lines, etc.

- extra workplace: underground, underwater, explosion-proof and other extra environment of the work equipment.

Next Product:HYDAC Filter Element

Products Category

Contact Us

Name: Allison Smith

Tel: +86-571-88617536

Fax: +86-71-88617536

Mobile: 17757181967

E-mail: [email protected]

Skype: .cid.7a9d6cc112abccc7

QQ: 3420904316

WeChat: wckek22

Whatsapp: +86 17757181967

Add: No.177 Xingqiao North Road, Hangzhou City, Zhejiang Province, China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online